|

|

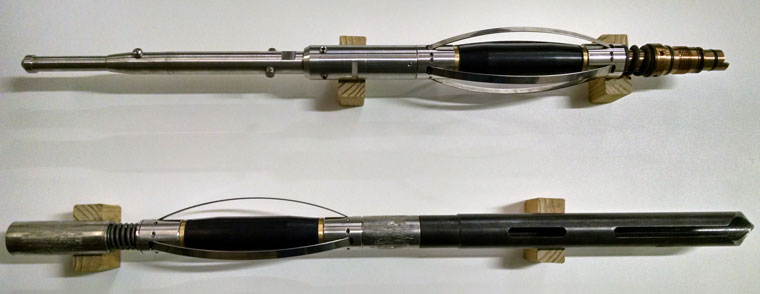

Reduces Orientation Time: Accurate has developed a Surface Recording Gyro (SRG) Orientation Spear point. This tool will allow Accurate to orient motors while sitting on top of retrievable MWD Systems resulting in rig time savings by eliminating Gyro and MWD tool trips and the need to time drill. Accurate has obtained patent Numbers US 7,506,699 B1 and US 7,506,700 B1 on this tool and its method. The tool has proven to reduce orientation time by more than 50%.

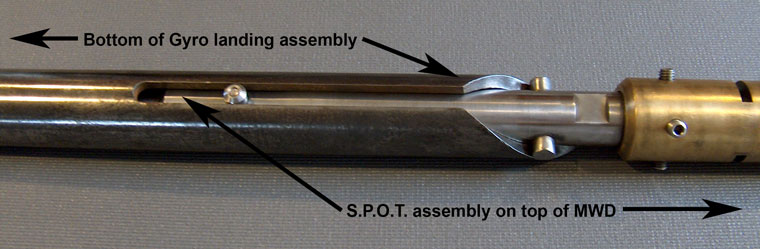

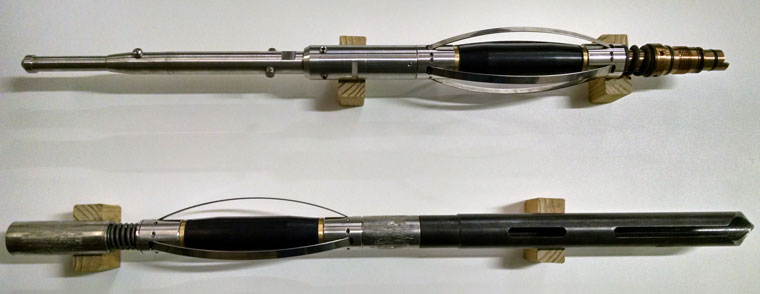

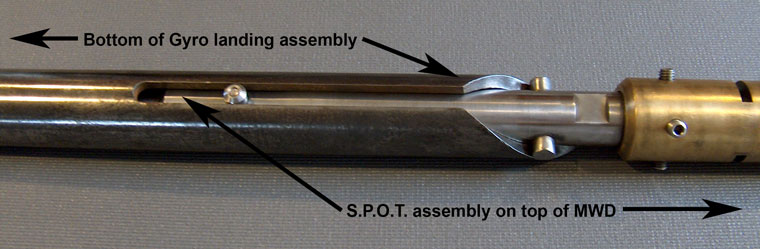

How it works: At surface, the SPOT is attached to the top of the retrievable MWD replacing their standard spear point. The spear point is oriented to match with the MWD tool face (High Side). The MWD is placed in the BHA at surface with our Spear Point Orientation Tool (SPOT) attached on top. SPOT will keep the MWD retrievable in the event of a tool failure or well control problems, and then reinserted without tripping the drill string. When KOP is reached, the SRG is tripped in the hole via a 5/16” electric line and sits on top (Piggyback) of the MWD. As the well is kicked off, the MWD is pulsing data as normal and the gyro is giving direction and tool face while drilling (Gyro Steering). Time drilling is not necessary due to the elimination of severe shock that occurs when Gyro Steering directly on top of the down hole motor. Tool face is more constant and higher flow rates can be achieved with the use of the spear point orientation tool (SPOT). When the MWD verifies a good tool face orientation, the SRG is tripped out of the hole and drilling continues. The spear point orientation tool (SPOT) is removed from the MWD when it is tripped out of the hole.

Reduces Orientation Cost: The spear point orientation tool (SPOT) eliminates the cost associated with tripping the Gyro and MWD in and out of the hole to verify good tool face reading by the MWD. The cost of time drilling, which can take as long as 18 to 24 hours, is eliminated. In many cases where gyro steering is utilized directly on top of the down hole motor, when the gyro is removed, trash will fall into the mule-shoe and the MWD will not obtain a good seat. In situations where trash plugs the mule-shoe, the drill string must be tripped to remove the obstruction. These costly occurrences can be eliminated by using the spear point orientation tool. Experienced directional drillers are completing the initial sidetrack off of the whipstock with the use of the Spear Point Orientation Tool (SPOT) and gyro steering in as little as 6 hours. |

| |

|

|

Click here to download a printable spec sheet.

|

|

|

|

|